The digital twin is a virtual copy of a physical object, which replicates in real time the movements and vital functions of the object in question. Florian Cantori and Rémi Ratajczak, robotics engineers from the Awabot Intelligence team, decipher this notion in the field of robotics for industry.

Principle of the digital twin

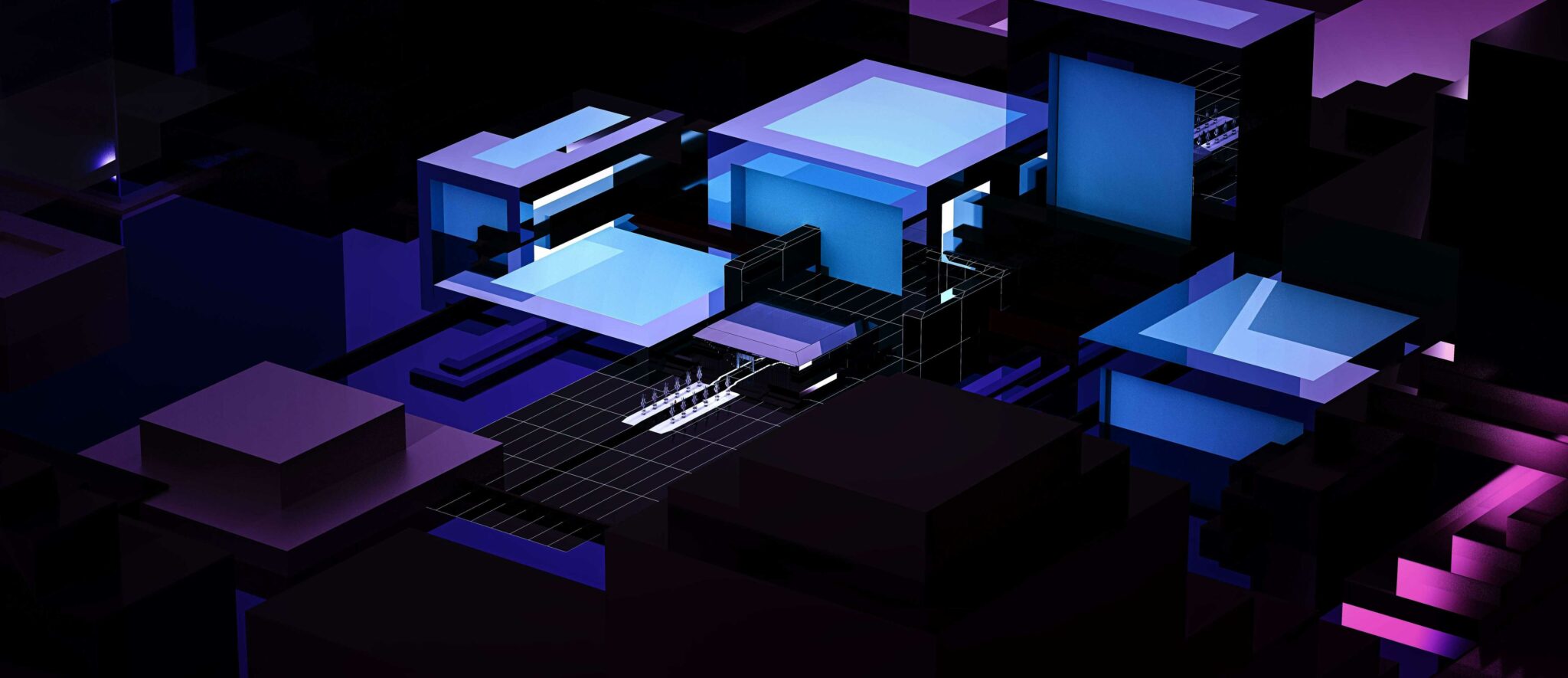

Rémi Ratajczak: “The digital twin corresponds in a way to the scanning of a document that we are used to with scanners, except that here it is a question of scanning and/or modeling in 3D complex objects, such as machines, vehicles or robots. We will not only scan the object, but also represent its functionalities in its context of use.

The digital twin makes it possible to reduce costs by “testing” functionalities in a realistic virtual world, or even interactions between machines in the same environment. In the industrial or logistic context, it allows to simulate the flow of products, people, assembly lines… And thus, to prototype the industrial environment in order to optimize its functioning and efficiency. In the transportation industry, the digital twin can be used to virtually size dynamic components (e.g., an engine) at lower cost by modeling the internal components of the element under study.”

Florian Cantori: “Indeed, the digital twin is interesting in the prototyping phase. The difficulty lies in maximizing the conformity of the digital model with the real model because there may be approximations, elements that are difficult to model and not necessarily representative of what exists.

Beyond the industrial environment, we have for example worked with a company specialized in ultrasound-based therapies, which wanted to evaluate the prototype of a new operating table. We established a real-time digital model reconciliation to simulate what was happening on the prototype: the interest was to make measurements and forecasts to better prevent possible collisions between the table and medical instruments.

For example, concerning this operating table in question, there was a very simple model originally but it did not replicate the deformation related to the weight of the patient. It would have been necessary to establish a finer model, taking into account the resistance of the materials and the deformation. Between the perfect digital model and reality, there can be positional gaps of a few millimeters. For this, we imagined with them a calibration step that allows for real-time readings that are configured in the digital model: this service allowed us to minimize the variances between the existing and the digital.”

Digital twin versus simulation

FC: “Unlike the digital twin, the simulation does not take into account the symmetry with reality. The simulation is purely virtual: we have a simulation environment in which we will make the object evolve, for example a robot, in which the latter must evolve. All of this is simulated and never leaves the virtual framework.”

RR: “The simulation service as proposed by Awabot Intelligence is based on the modeling of an “empty shell”, devoid of the object’s internal functions. This allows us to test high-level functionalities (e.g., autonomous navigation, computer vision) on a 3D model equipped with virtual sensors, representative of a finished product.

The hardware integration and the development of drivers adapted to the robots are managed in parallel or upstream by our teams (on real hardware) in order to minimize the time-to-product. However, it is important to note that the underlying physical concepts (e.g., internal functioning of an electric motor) can also be modeled in simulation, provided that the appropriate tools are available.”

As part of its robotics services related to digital twins, Awabot Intelligence thus intervenes at two levels:

- the integration of digital twins, to carry out development in simulation;

- the generation of 3D models of environments (3D maps), based on visual SLAM.

Synergies between augmented reality and digital twins

FC: “Beyond 3D modeling, there is augmented reality which has a concrete application. The idea is, for example, to evolve in an existing industrial environment and thanks to digital twin tools transposed into the 3D model, to visualize objects in augmented reality in the real environment at the moment. Very interesting for industrialists!”

RR: “Augmented reality coupled with AI is also of interest for visual analysis of a given environment. By superimposing a perfect or previously observed 3D model, it is possible to estimate the modifications that have occurred (e.g., on a building, on a machine) and to quantify their impact. This allows people in the field to have visual access to the elements of concern and thus save time in their work. In the near future, this will also be possible remotely, thanks to the augmented telepresence technologies currently being developed by Awabot…”

Would you like to discuss a project related to the topic covered in this article? With complementary know-how and skills covering all the issues related to robotics, the Awabot Intelligence team will accompany you.